Description

Specifications

| Product model | IPRM-G-ETW |

| Measurement item | Refractive Index (nD), Brix, ,temperature. |

| Measuring range | 0.00 – 70 .00% Brix |

| Resolution | 0.01% Brix |

| Measurement accuracy | ± 0.3% Brix |

| Brix range | Temperature corrected 5 – 60°C |

| Process temperature5 | -10°C up to +70°C |

| Prism | Sapphire |

| Wetted parts | Stainless Steel SUS 316L, optional: HastelloyC-276 |

| Power supply | 24 V DC |

| Interfaces | 1 output 4 – 20 mA,1 serial output RS485 |

| International Protection class | Display surface:IP65 Water resistant |

| Process pressure | Max. 1 MPa (145 psi, 10 bar) |

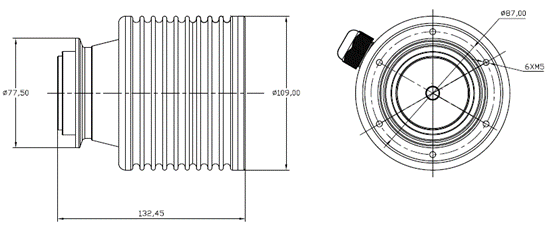

| Dimensions and weight | length 138 x diam.109mm; approx. 1870g |

| Cleaning components Options | IPRM-US, IPRM-Wiper |

| Fitting Options | IDF/ISO clamp union (1-3 inches), Flange, Compression Fitting G1/4 |

Dimensions

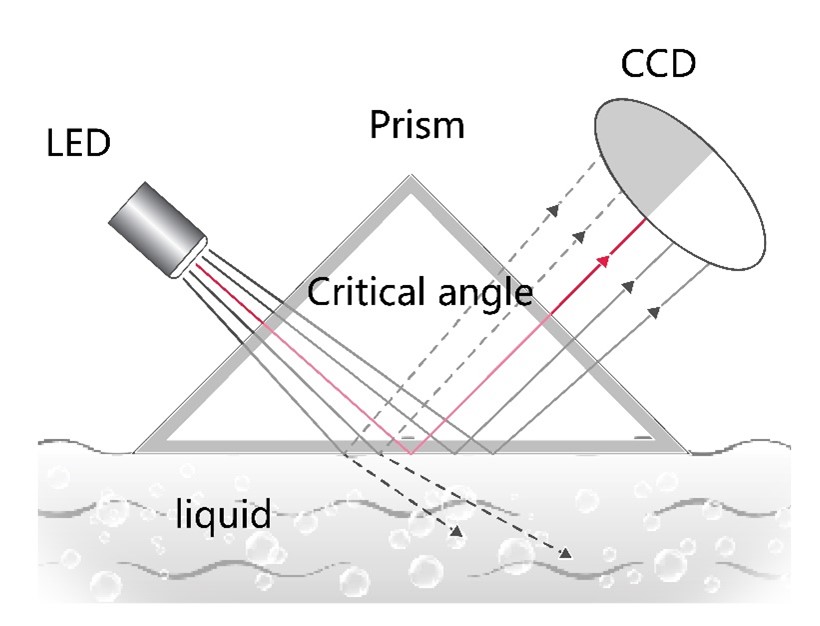

Measurement Principles

The refraction of light is a phenomenon wherein the direction that light is traveling changes as it passes through different mediums.

Through this phenomenon, we can observe as light’s direction changes and the “bent” appearance of substances even in the seemingly familiar, ordinary places in our day to day lives.

For example, imagine the lens of a pair of glasses and a pool.

When looking through the lens, an object appears larger or smaller than it is in reality.

When standing inside a pool, as you peer downward from the water’s surface, your legs will look shorter than they actually are.

As light moves from medium A (in this case, air) to medium B (lens and the pool’s water), it refracts.

Furthermore, it is known that light’s refraction changes depending on the concentration of a liquid.

The refractive index, which is a value that expresses the degree of refraction, is proportional to the density (mixture ratio) of a component.

Therefore, if there is 10g of sugar contained in 100ml of an aqueous solution and 20g of sugar contained in 100ml of an aqueous solution, the latter will have a higher refractive index value.

This difference in refractive index due to concentration variance has also been confirmed in solutions other than sucrose.

The properties of both the phenomenon known as the refraction of light and differing refractive index depending on concentration, are used as the principles of refractometers.

In addition to measuring the refractive index of a liquid, refractometers also display the concentration, converted from the refractive index.

Product introduction

Xylitol inline refractometer analyzer, also known as xylitol inline refractometer, xylitol inline refractometer meter, is a high-precision optical instrument that measures the refractometer of solution based on the principle of light refraction and total reflection. The inline refractometer analyzer is installed on the production line to detect the samples flowing through the pipeline or tank of the production line to ensure the sample qualification rate and the normal operation of the production process. Through inline instruments and automated production equipment, it helps enterprises improve production efficiency, manual automation, reduce labor costs, reduce production costs, and effectively ensure the uniformity and stability of product quality.

Product features

Based on the principle of refraction of light, it is widely used in the online detection of xylitol solution concentration

Product advantages

● It is not affected by the color, turbidity and viscosity of the material to be measured

● Not affected by bubbles, solid impurities and crystals in the material

● It is not affected by liquid pressure changes, flow changes, turbulent flow phenomena

● No mechanical action measurement, ensure stability and long life

● The detection prism is an optical grade sapphire prism, which is resistant to scratches, scratches and abrasion

● Detection of prism full-plane structure; No reagent consumables are required to run, and low power consumption

● With automatic temperature compensation function, the measurement accuracy is not affected by temperature

● Integrated measurement and display; Support panel and Bluetooth communication settings, view parameters

● 4-20mA/RS485; Built-in alarm, cleaning and switching signal output

● With 15 years of industry application experience, Chuyi Measurement and Control provides customers with the most complete product application solutions

● Chuyi Measurement and Control’s laboratory can provide data modeling and testing services for customers’ specific solutions

Application highlights

Xylitol can replace sugar for candy, pastries, and beverages according to normal production needs. On the label, it is indicated that it is suitable for diabetics. In actual production, xylitol can be used as a sweetener and humectant. The reference dosage for food is: chocolate, 43%; chewing gum, 64%; jam, jelly, 40%; Seasoning tomato paste, 50%. Xylitol is also used in condensed milk, toffee, gummies, etc.

The IPRM-G-ETW XYLITOL inline-refractometer is used to monitor the refractometer of xylitol solution in the production line in real time.